Welding fixture for one piece Grip safety

3 posters

Page 1 of 1

Welding fixture for one piece Grip safety

Welding fixture for one piece Grip safety

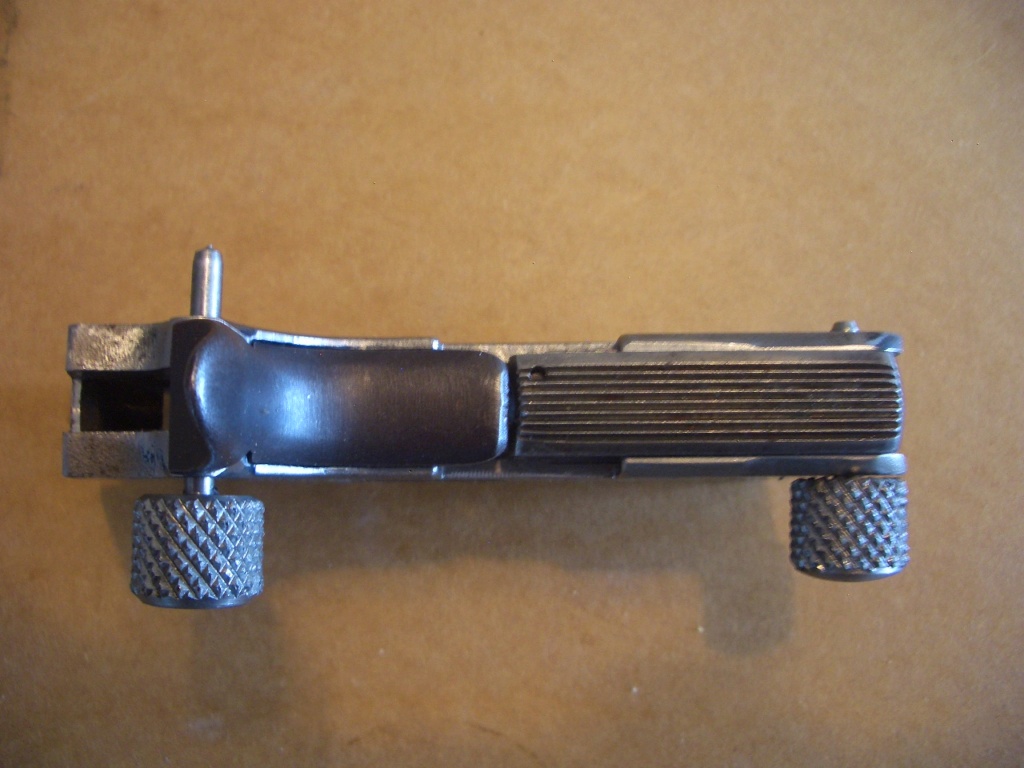

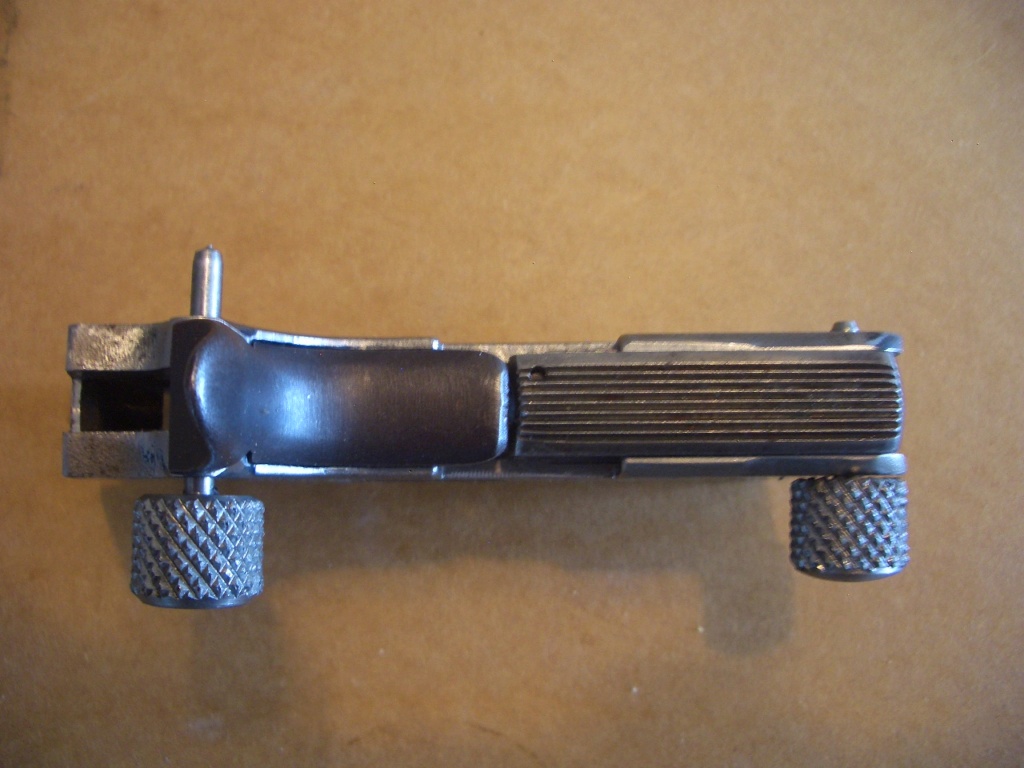

Making progress on my .22 conversion, I modified the frame (Caspian) to accept Beaver-tail grip safety. However I like a one piece grip safety/main spring housing so I made a welding fixture from a de-milled frame Caspian sent. I might make another thought this one will work. I had to tweak the dimensions so that the welded assembly will fit the Caspian completed frame I'm using for the conversion. In making the fixture I found why Caspian scrapped it, It's SS and not casted correctly, Sides were milled but I found it was not flat or parallel so I put the frame in my surface grinder. I would have been better off making if from a piece of steel! But after changing dimensions the welded assembly will fit my conversion frame!

Froneck- Posts : 1693

Join date : 2014-04-05

Age : 76

Re: Welding fixture for one piece Grip safety

Re: Welding fixture for one piece Grip safety

Nice.

I forgot the Caspian frames are investment cast. Worked on one for my cousin a number of years back. Stainless frame, Damascus slide and MS housing. No MSH was available, but the supplier sent him some scrap pieces and I machined one for him. Left the back face 'square' for fitting ... and saved me the hassle of contouring it.

There was 'something' about the frame that required tweaking the MSH to fit. Don't remember what, but I wasn't terribly impressed ... and yet they're favored by at least one master pistolsmith ... Maybe his was a fluke ...

I've seen some ugly stuff with a couple of Rugers, revolver and a bolt action. Maybe my family is cursed ...

I forgot the Caspian frames are investment cast. Worked on one for my cousin a number of years back. Stainless frame, Damascus slide and MS housing. No MSH was available, but the supplier sent him some scrap pieces and I machined one for him. Left the back face 'square' for fitting ... and saved me the hassle of contouring it.

There was 'something' about the frame that required tweaking the MSH to fit. Don't remember what, but I wasn't terribly impressed ... and yet they're favored by at least one master pistolsmith ... Maybe his was a fluke ...

I've seen some ugly stuff with a couple of Rugers, revolver and a bolt action. Maybe my family is cursed ...

WesG- Posts : 647

Join date : 2018-09-21

Location : Cedar Park, TX - N CA

Re: Welding fixture for one piece Grip safety

Re: Welding fixture for one piece Grip safety

There was quite a bit on the frame that was not machined. To demil the slide as they call is so it can be sold without serial number is to cut at the location from slide stop opening to magazine catch hole. That cut on the frame as seen in the photos was as it was received.The top of the frame was not machined so to get a reference I put pins in the plunger tube holes since they are parallel with the top and indicated the pins. Then milled the top surface flat. The rear was also not machined so I indicated the back side and cut the opening for the grip safety and main spring housing but when I went to drill the hole for the main spring housing pin I found the the rear angle was not correct, Hole for the grip and thumb safety was drilled and reamed, the fact that the main spring hole was not drilled should have told me something. Being I was using a Jig borer my locations were correct to a ten thousandth of and inch. I then put my completed frame in the Jig Borer and with gauge pins found where the hole needed to be! Not sure how it was casted but it was casted, areas like the front wrap around and slight surface on the sides of the grip safety and main spring were very smooth. Magazine opening is good too, magazine will fit, a bit snug, will not fall out by it's own weight but is not hard to push in. Areas that would have needed to be machined were rough as any casted surface is. There is an error in the casting but I didn't spend time trying to determine what. After all it's a welding fixture but the holes for the grip safety and main spring housing must be correct or the welded assembly will not fit the frame I intend to use it in!

Caspian set me two of these frames, at the time, I couldn't use it because too much was removed from the front, I needed more of the trigger location to use to measure trigger shoe fit. They then sent another that I use for that purpose.

Caspian set me two of these frames, at the time, I couldn't use it because too much was removed from the front, I needed more of the trigger location to use to measure trigger shoe fit. They then sent another that I use for that purpose.

Froneck- Posts : 1693

Join date : 2014-04-05

Age : 76

Re: Welding fixture for one piece Grip safety

Re: Welding fixture for one piece Grip safety

Froneck.

If you don't mind me asking, what function does the unitized grip safety and mainspring housing have? What problem does it solve for you? Is there some requirement for it in your .22 conversion build? You have gone to a lot of work on this welding jig and I was curious as to why. Good luck with your most interesting project.

If you don't mind me asking, what function does the unitized grip safety and mainspring housing have? What problem does it solve for you? Is there some requirement for it in your .22 conversion build? You have gone to a lot of work on this welding jig and I was curious as to why. Good luck with your most interesting project.

PacFltShooter- Posts : 56

Join date : 2019-03-08

Age : 68

Location : Illinois

PacFltShooter- Posts : 56

Join date : 2019-03-08

Age : 68

Location : Illinois

Re: Welding fixture for one piece Grip safety

Re: Welding fixture for one piece Grip safety

The beaver-tail on the safety works backwards. Upward pressure on the beaver-tail forces the safety out. Another issue is long ago I cut my index finger off below the knuckle so I have about a 1" stub. I use my middle finger on the trigger. I would think others have problems too since the grip safetys of various types have added material or a lump to aid in pushing the safety in. I don't like the added material or lump!

I addition I add stair anti slip adhesive "sandpaper" to it and the mainspring housing. One piece is allowed on what NRA calls custom made guns. I had it ruled upon at Camp Perry. But if you have a grip saftey and prevent it from working possibly by pinning in place, it's not allowed!

Fixture worked great, welding has been completed and is in the frame shown in Homemade .22 conversion Progress. I'm getting rust blue solution and as soon a I get it the grip safety will be the first test piece..

After welding the hammer strut slot in the grip safety had to be milled to allow the spring, cap and retainer pin to be installed. I used a ball endmill and filed the radius left at the holes edge.

I addition I add stair anti slip adhesive "sandpaper" to it and the mainspring housing. One piece is allowed on what NRA calls custom made guns. I had it ruled upon at Camp Perry. But if you have a grip saftey and prevent it from working possibly by pinning in place, it's not allowed!

Fixture worked great, welding has been completed and is in the frame shown in Homemade .22 conversion Progress. I'm getting rust blue solution and as soon a I get it the grip safety will be the first test piece..

After welding the hammer strut slot in the grip safety had to be milled to allow the spring, cap and retainer pin to be installed. I used a ball endmill and filed the radius left at the holes edge.

Froneck- Posts : 1693

Join date : 2014-04-05

Age : 76

Re: Welding fixture for one piece Grip safety

Re: Welding fixture for one piece Grip safety

Ok so now it all makes sense. Thanks for that very detailed explanation. I await your rust blue results. Should be quite the pistol!

PacFltShooter- Posts : 56

Join date : 2019-03-08

Age : 68

Location : Illinois

Re: Welding fixture for one piece Grip safety

Re: Welding fixture for one piece Grip safety

If anyone wanted to make that fixture I suggest you contact Caspian or maybe other frame makers have frames with bad errors. Caspian will sell those and call them de-milled so as they don't require serial numbers or FFL. If you call ask for the one that has the rear of the frame complete. That way the hole centers and opening is as needed, nothing else matters. Weld opening can easily be cut with hacksaw or grinder. If you don't have a mill cut the hammer strut round so the parts needed in the mainspring housing can be inserted. Round chainsaw file will work. 5/32" rod can be used as pins, long #8 socket head cap screw with threads removed, will require filing the OD because it's a few thousandths big.

Froneck- Posts : 1693

Join date : 2014-04-05

Age : 76

Similar topics

Similar topics» help with grip safety

» Looking for a Better Grip Safety

» Fitting a grip safety

» Grip safety issue

» Why 1911 Grip Safety?

» Looking for a Better Grip Safety

» Fitting a grip safety

» Grip safety issue

» Why 1911 Grip Safety?

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum|

|

|