A Machine Checkering Fixture

+7

AC Baker

Cmysix

samtoast

Tripscape

jglenn21

james r chapman

Dr.Don

11 posters

Page 1 of 1

A Machine Checkering Fixture

A Machine Checkering Fixture

I have a nice set of checkering files and have done a fair amount of checkering to small items like mainspring housings and such. But the amount of effort required and the potential for disaster always dissuaded me from trying to hand checker 1911 front straps. I know that various gunsmiths machine checker these, but I have never seen a fixture for doing this offered for sale anywhere. I have a lathe, small mill, and a rotary table so I decided to see if I could come up with my own machine checkering fixture.

The first problem is to get the frame aligned with the rotational axis of the rotary table. For this I made a spindle. One end is turned to a #2 Morse taper to fit my rotary table. The rest is turned to a diameter of 0.550”, which seemed to fit the interior of the front strap of most of the 1911 frames I had available to try. The spindle is shown here with a cross bolt with a broad flat head which can be jammed against the flat back of the magazine well to fix the frame in place on the spindle.

With the frame and spindle mounted on the rotary table use a dial indicator to determine whether the rotational radius of the frame is correct. That is, does the indicator vary as the table is turned.

I found that I needed to shim the frame out about 0.040” to get the rotational radius correct. I used a piece of 0.040” brass rod between the spindle and frame interior to accomplish this.

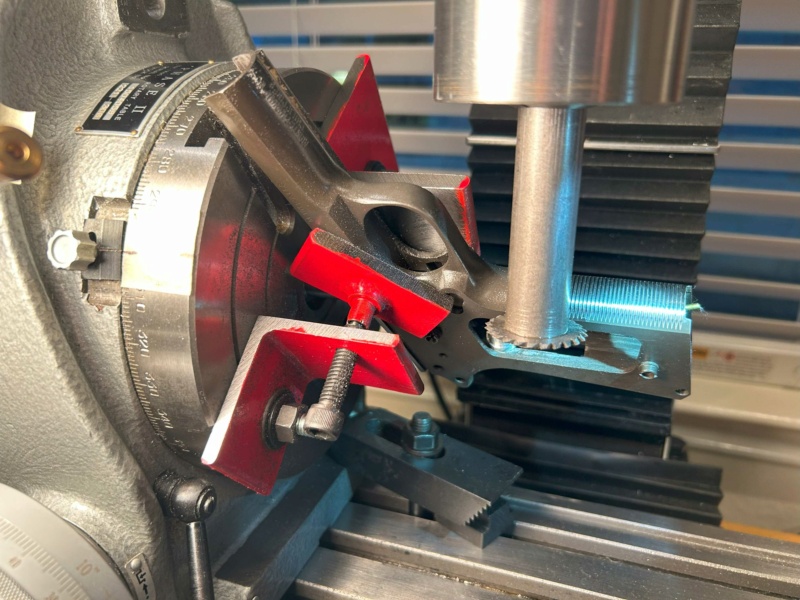

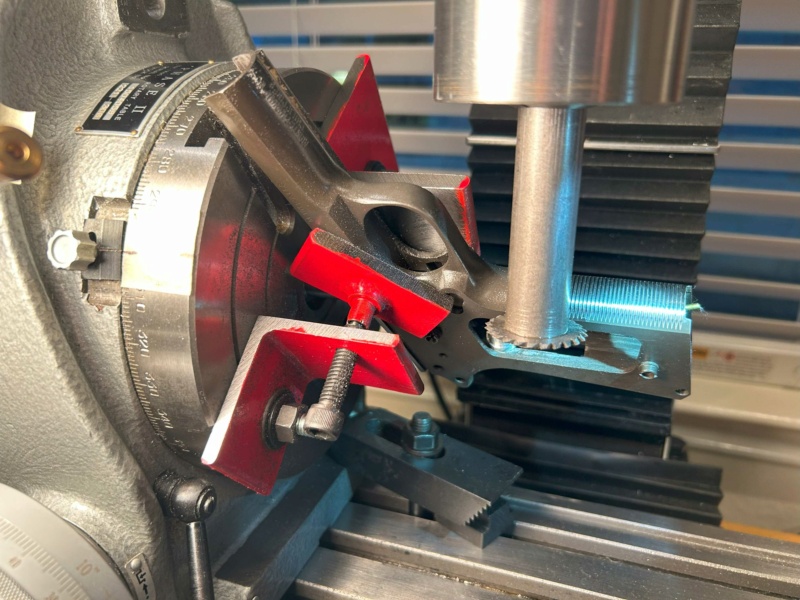

While the frame/spindle arrangement feels quite firm, it needs more support to stay in place under the cutting forces of the mill. For that I made a two-piece vise I could mount on the rotary table face. It is shown in the next photo.

With the fixture completed the first step in the process is to mount the rotary table on the mill table and precisely align the rotary table axis with the mill spindle axis. A coaxial indicator is the best means of doing this. The Y table axis of the mill is then locked in place and only the X-axis is used for controlling the cutter depth. Once this is done, the spindle, frame, and vise are mounted on the rotary table.

Before any checkering cuts were made a long reach end mill was used to even up the frame radius. You only want to take a few thousandths off here for fear of thinning the front strap too much to support checkering.

A 60 degree cutter was used to make the checkering cuts. I obtained mine from EGW. My mill has a digital readout on the Z-axis and allowed me to precisely control the spacing of the horizontal cuts on the frame.

With the horizontal cuts complete, the rotary table is reset on the mill for what will be the vertical cuts on the front strap. Leave the frame in the fixture when resetting the rotary table to its new position. The table must be set so the frame is accurately aligned with the X-axis of the mill. Otherwise the depth of cut will vary from one end to the other. Use a dial indicator to check this.

Release the lock on the mill’s Y-axis and use the Y-axis controls to set the depth of each cut. The Z-axis position of the cutter should be set so it is precisely mid-frame when the frame is rotated to a horizontal position. This will cause all of the cuts to be pointed precisely at the center of rotation of the frame. You will probably need to do some calculations based upon the radius of rotation of your frame setup to determine how much to rotate the table for each cut. For my setup, and using 20 line-per-inch checkering, the table needed to be rotated 6.4 degrees (6 degrees and 24 minutes) for each cut.

I should note that it is difficult to see the cutter in operation in this arrangement. Be sure and use a piece of tape on the mill with a mark on it to indicate where you are to stop the cut. You do not want these cuts to end in different places on the frame.

My first attempt using this fixture turned out reasonably well. The next one should be better.

It is 20 lines per inch, and I used a cutter depth of 0.025”. I think next time I would increase that to at least 0.030” to bring the points to a slightly sharper profile.

I realize not everyone has access to the machinery required to do machine checkering. But some folks do, and perhaps some will be inspired to share their own fixtures and approaches to this job. I also thought that the process might be interesting even to those who don’t have access to the machinery described here. And for those who do it all by hand, you have my deep admiration.

The first problem is to get the frame aligned with the rotational axis of the rotary table. For this I made a spindle. One end is turned to a #2 Morse taper to fit my rotary table. The rest is turned to a diameter of 0.550”, which seemed to fit the interior of the front strap of most of the 1911 frames I had available to try. The spindle is shown here with a cross bolt with a broad flat head which can be jammed against the flat back of the magazine well to fix the frame in place on the spindle.

With the frame and spindle mounted on the rotary table use a dial indicator to determine whether the rotational radius of the frame is correct. That is, does the indicator vary as the table is turned.

I found that I needed to shim the frame out about 0.040” to get the rotational radius correct. I used a piece of 0.040” brass rod between the spindle and frame interior to accomplish this.

While the frame/spindle arrangement feels quite firm, it needs more support to stay in place under the cutting forces of the mill. For that I made a two-piece vise I could mount on the rotary table face. It is shown in the next photo.

With the fixture completed the first step in the process is to mount the rotary table on the mill table and precisely align the rotary table axis with the mill spindle axis. A coaxial indicator is the best means of doing this. The Y table axis of the mill is then locked in place and only the X-axis is used for controlling the cutter depth. Once this is done, the spindle, frame, and vise are mounted on the rotary table.

Before any checkering cuts were made a long reach end mill was used to even up the frame radius. You only want to take a few thousandths off here for fear of thinning the front strap too much to support checkering.

A 60 degree cutter was used to make the checkering cuts. I obtained mine from EGW. My mill has a digital readout on the Z-axis and allowed me to precisely control the spacing of the horizontal cuts on the frame.

With the horizontal cuts complete, the rotary table is reset on the mill for what will be the vertical cuts on the front strap. Leave the frame in the fixture when resetting the rotary table to its new position. The table must be set so the frame is accurately aligned with the X-axis of the mill. Otherwise the depth of cut will vary from one end to the other. Use a dial indicator to check this.

Release the lock on the mill’s Y-axis and use the Y-axis controls to set the depth of each cut. The Z-axis position of the cutter should be set so it is precisely mid-frame when the frame is rotated to a horizontal position. This will cause all of the cuts to be pointed precisely at the center of rotation of the frame. You will probably need to do some calculations based upon the radius of rotation of your frame setup to determine how much to rotate the table for each cut. For my setup, and using 20 line-per-inch checkering, the table needed to be rotated 6.4 degrees (6 degrees and 24 minutes) for each cut.

I should note that it is difficult to see the cutter in operation in this arrangement. Be sure and use a piece of tape on the mill with a mark on it to indicate where you are to stop the cut. You do not want these cuts to end in different places on the frame.

My first attempt using this fixture turned out reasonably well. The next one should be better.

It is 20 lines per inch, and I used a cutter depth of 0.025”. I think next time I would increase that to at least 0.030” to bring the points to a slightly sharper profile.

I realize not everyone has access to the machinery required to do machine checkering. But some folks do, and perhaps some will be inspired to share their own fixtures and approaches to this job. I also thought that the process might be interesting even to those who don’t have access to the machinery described here. And for those who do it all by hand, you have my deep admiration.

Dr.Don- Posts : 808

Join date : 2012-10-31

Location : Cedar Park, TX

chiz1180, Chase Turner, AC Baker, Dan Webb, JRV, DK and TXTad like this post

Re: A Machine Checkering Fixture

Re: A Machine Checkering Fixture

So, what’s the address for us to send all our frames!!

james r chapman- Admin

- Posts : 6085

Join date : 2012-01-31

Age : 75

Location : HELL, Michigan

Pinetree likes this post

Re: A Machine Checkering Fixture

Re: A Machine Checkering Fixture

Don, the Keller fixture is designed for this job. Sold by Cylinder and Slide. You have to do a lot of frames to justify it though.

Nice setup and work

Nice setup and work

jglenn21- Posts : 2575

Join date : 2015-04-07

Age : 75

Location : monroe , ga

Carl Taylor and Chase Turner like this post

Re: A Machine Checkering Fixture

Re: A Machine Checkering Fixture

Wow, amazing job. I applaud you! Looks very professionally made.

Tripscape- Posts : 829

Join date : 2019-03-23

Gustavo1957 likes this post

Re: A Machine Checkering Fixture

Re: A Machine Checkering Fixture

jglenn21,

Thanks for the info. I was unaware of the Keller fixture. Agree it would take a lot of work to cover the investment in it.

Don

Thanks for the info. I was unaware of the Keller fixture. Agree it would take a lot of work to cover the investment in it.

Don

Dr.Don- Posts : 808

Join date : 2012-10-31

Location : Cedar Park, TX

Re: A Machine Checkering Fixture

Re: A Machine Checkering Fixture

thank you very much for documenting and sharing the process. Very helpful and inspiring!

samtoast- Posts : 140

Join date : 2022-10-03

Re: A Machine Checkering Fixture

Re: A Machine Checkering Fixture

james r chapman wrote:So, what’s the address for us to send all our frames!!

DITTO, you need practice, I got frames

Cmysix- Posts : 330

Join date : 2022-12-23

Age : 65

Location : Opelika Alabama

Re: A Machine Checkering Fixture

Re: A Machine Checkering Fixture

Very nice, thanks for sharing!

AC Baker- Posts : 14

Join date : 2020-05-27

Age : 60

Location : Milford Sq., Pa

Re: A Machine Checkering Fixture

Re: A Machine Checkering Fixture

Very interesting. I really enjoy these kinds of posts.

rfmiller- Posts : 113

Join date : 2012-08-19

Age : 70

Location : Missouri

Re: A Machine Checkering Fixture

Re: A Machine Checkering Fixture

Thank you for sharing your innovative approach.

denpython- Posts : 10

Join date : 2013-10-28

Re: A Machine Checkering Fixture

Re: A Machine Checkering Fixture

Thread mills are a readily available source for checkering cutters. I've used them for the "long" cuts for years. Been meaning to make a fixture for the cross cuts, but haven't gotten arround to it.

Double angle cutters also work, but have a larger diameter so you can't get quite as high.

https://www.suncoasttools.com/crm/ItemPage.aspx?ItemNumber=89TM-3/8+++SNGFORM66&VendorNumber=MELIN&Code=GOOGLEFEED

Double angle cutters also work, but have a larger diameter so you can't get quite as high.

https://www.suncoasttools.com/crm/ItemPage.aspx?ItemNumber=89TM-3/8+++SNGFORM66&VendorNumber=MELIN&Code=GOOGLEFEED

10sandxs- Posts : 939

Join date : 2016-01-29

Re: A Machine Checkering Fixture

Re: A Machine Checkering Fixture

Clark Custom Guns has an interesting video on how they do checkering.

https://www.youtube.com/watch?v=Xu1kV5ndz2w

https://www.youtube.com/watch?v=Xu1kV5ndz2w

8eightring- Posts : 175

Join date : 2011-06-17

Location : Ohio

troystaten likes this post

Re: A Machine Checkering Fixture

Re: A Machine Checkering Fixture

10sandxs,

The thread mill is a good suggestion. I used a double angle cutter almost 1 1/2" in diameter. The much smaller diameter of the thread mill would allow full depth cuts with much less overrun at the end on the long vertical cuts. It would also let you get higher as you mentioned.

Don

The thread mill is a good suggestion. I used a double angle cutter almost 1 1/2" in diameter. The much smaller diameter of the thread mill would allow full depth cuts with much less overrun at the end on the long vertical cuts. It would also let you get higher as you mentioned.

Don

Dr.Don- Posts : 808

Join date : 2012-10-31

Location : Cedar Park, TX

Re: A Machine Checkering Fixture

Re: A Machine Checkering Fixture

And thier carbide... cuts nice...Dr.Don wrote:10sandxs,

The thread mill is a good suggestion. I used a double angle cutter almost 1 1/2" in diameter. The much smaller diameter of the thread mill would allow full depth cuts with much less overrun at the end on the long vertical cuts. It would also let you get higher as you mentioned.

Don

10sandxs- Posts : 939

Join date : 2016-01-29

Similar topics

Similar topics» Checker front strap

» Benelli MP95E Ransom fixture

» Barrel Testing Fixture Question

» Hand Checkering advice

» Kitchen Table Checkering

» Benelli MP95E Ransom fixture

» Barrel Testing Fixture Question

» Hand Checkering advice

» Kitchen Table Checkering

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum|

|

|