148g HBWC skirt separation

+4

bruce martindale

David H

Wobbley

djw1cav

8 posters

Page 1 of 1

148g HBWC skirt separation

148g HBWC skirt separation

This past January I was trying to eliminate leading in my S&W model 52-2 barrel. I posted a request for help (on this forum) and one of the responses was to try Bear Creek moly coated bullets (thanks Ashley!). I purchased 500 Bear Creek bullets and loaded them like I load my Zero and Remington bullets. Initially I had terrible results, the groups were in the 4" to 5" range. On the upside, I found them to be clean and so easy to load that I kept on trying different loads. After 17 attempts I finally found a load that groups as good as my Remington and Zero bullet loads AND had no leading after 65 rounds.

Now for my question. The Bear Creek bullets grouped best with 2.8g of WST. Unfortunately, i had an occasional failure to extract at 2.8g so I increased the charge to 2.9g WST. At that charge the average velocity was 756 with a high of 770 (the sample size was 10). Considering the sample size and how the bell curve works I expect the max velocity could approach 800. Should I be concerned about skirt separation with this load?

Doug

Now for my question. The Bear Creek bullets grouped best with 2.8g of WST. Unfortunately, i had an occasional failure to extract at 2.8g so I increased the charge to 2.9g WST. At that charge the average velocity was 756 with a high of 770 (the sample size was 10). Considering the sample size and how the bell curve works I expect the max velocity could approach 800. Should I be concerned about skirt separation with this load?

Doug

djw1cav- Posts : 200

Join date : 2015-04-06

Age : 75

Location : Illinois

Re: 148g HBWC skirt separation

Re: 148g HBWC skirt separation

No, I don’t think so. For two reasons, First, the average velocity of factory is around 770 fps and you’re very near that mark. If the velocity is the same , then very likely the pressure is the same. Second, I have loaded Speer HBWC with 3.1 gr Red Dot (

). DON’T EVER LOAD THAT MUCH!!!!! Those gave a velocity very much higher (900 from a 10 inch) and no skirt separation.

). DON’T EVER LOAD THAT MUCH!!!!! Those gave a velocity very much higher (900 from a 10 inch) and no skirt separation.

I also think that skirt separation is very much a bullet construction issue as much as overload issue. There were a few issues in Europe with European bullets, but the problem seems less here with American bullets.

). DON’T EVER LOAD THAT MUCH!!!!! Those gave a velocity very much higher (900 from a 10 inch) and no skirt separation.

). DON’T EVER LOAD THAT MUCH!!!!! Those gave a velocity very much higher (900 from a 10 inch) and no skirt separation. I also think that skirt separation is very much a bullet construction issue as much as overload issue. There were a few issues in Europe with European bullets, but the problem seems less here with American bullets.

Wobbley- Admin

- Posts : 4653

Join date : 2015-02-12

148 gr. skirt

148 gr. skirt

Federal Match velocity is 710, on there 148 gr. match ammo

David H- Posts : 81

Join date : 2018-08-02

Re: 148g HBWC skirt separation

Re: 148g HBWC skirt separation

Ashley,

I think you are correct about construction of the bullet. In my favor the Bear Creek has a thicker walled skirt than my Zeros or Remmington's which should give it the ability to withstand higher velocities.

Another factor which has me concerned it at 2.8gWST my velocity was 718 and at 2.9WST is jumped to 756! That seems like a big increase for a small amount of powder.

What bullet did you push to 900?

By the way I tested some Winchester factory match 148HBWC and the average velocity was 727.

Doug

I think you are correct about construction of the bullet. In my favor the Bear Creek has a thicker walled skirt than my Zeros or Remmington's which should give it the ability to withstand higher velocities.

Another factor which has me concerned it at 2.8gWST my velocity was 718 and at 2.9WST is jumped to 756! That seems like a big increase for a small amount of powder.

What bullet did you push to 900?

By the way I tested some Winchester factory match 148HBWC and the average velocity was 727.

Doug

djw1cav- Posts : 200

Join date : 2015-04-06

Age : 75

Location : Illinois

Re: 148g HBWC skirt separation

Re: 148g HBWC skirt separation

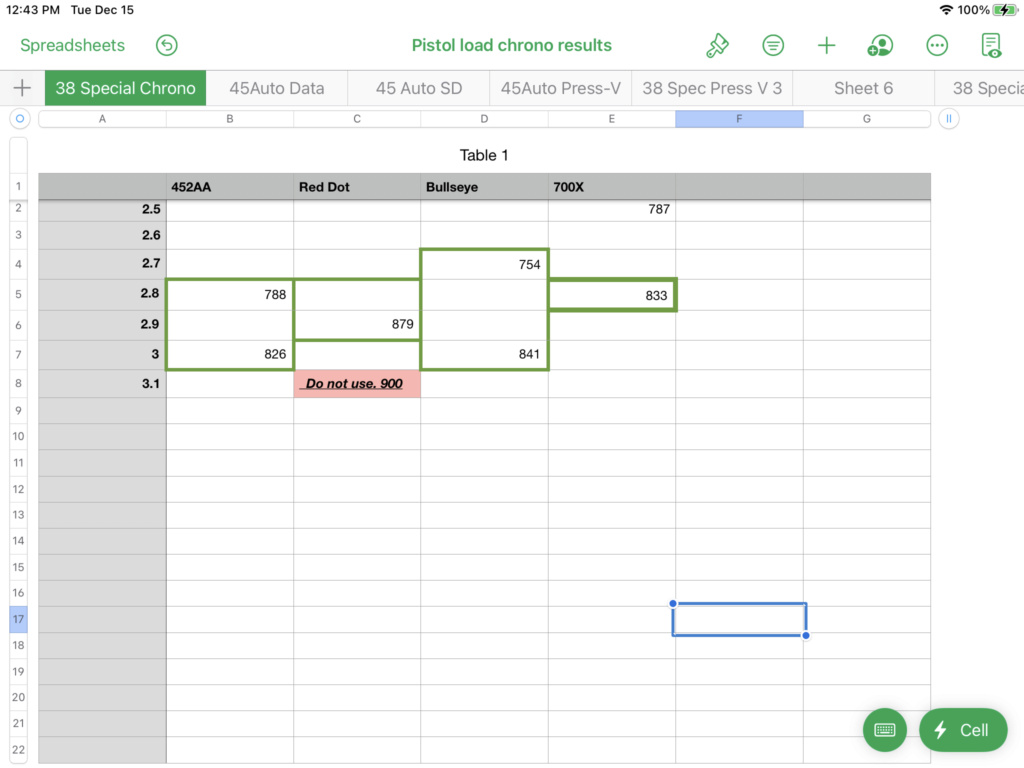

Here is my chart. The test gun is a 10 inch Contender so I can use my magneto speed, the velocity is about 40-50 fps faster . The 452AA is very close to WST but is not the same…. These are Speer bullets.

With the exception of the 3.1 RD, I shot the residual ammo at a target using my 52. The best powders were 452AA and Bullseye, hard to pick between the two. The two loads were fired on the same target and gave a big blob at 25 yards. The 3.1 were shot in the Contender.

Wobbley- Admin

- Posts : 4653

Join date : 2015-02-12

Re: 148g HBWC skirt separation

Re: 148g HBWC skirt separation

Ashley,

Thanks for the detailed reply. You have taken away my concern about skirt separation. Now it's time to buy more Bear Creek and start loading.

Doug

Thanks for the detailed reply. You have taken away my concern about skirt separation. Now it's time to buy more Bear Creek and start loading.

Doug

djw1cav- Posts : 200

Join date : 2015-04-06

Age : 75

Location : Illinois

Wobbley likes this post

Re: 148g HBWC skirt separation

Re: 148g HBWC skirt separation

One case where you do have to worry about skirt separation is with OLD bullets. They have undergone precipitation hardening and became brittle. Otherwise for target level loads (730 fps) you’re fine with most powders. To reduce chamber fowling, I use an oiled stamp pad and roll my shells across . Improves function a lot

Re: 148g HBWC skirt separation

Re: 148g HBWC skirt separation

Bruce,bruce martindale wrote:One case where you do have to worry about skirt separation is with OLD bullets. They have undergone precipitation hardening and became brittle. Otherwise for target level loads (730 fps) you’re fine with most powders. To reduce chamber fowling, I use an oiled stamp pad and roll my shells across . Improves function a lot

I did not know that is an issue with OLD lead bullets. When does an old bullet become a potential problem? I have some Remington HBWC's that are 5 or 6 years old. (I have been saving them for when I become a better shot). Are they a concern?

Doug

djw1cav- Posts : 200

Join date : 2015-04-06

Age : 75

Location : Illinois

Re: 148g HBWC skirt separation

Re: 148g HBWC skirt separation

I’m not sure that old bullets of commercially pure or 2%SB alloys will precipitation harden even if centuries old. Most swaged alloy bullets are fairly soft and do not have enough alloying to precipitation harden.

https://www.bullseyeforum.net/t7834-swaged-bullets

https://www.bullseyeforum.net/t7834-swaged-bullets

Wobbley- Admin

- Posts : 4653

Join date : 2015-02-12

Re: 148g HBWC skirt separation

Re: 148g HBWC skirt separation

Doug: not a problem. If they can be indented with a thumbnail, they’re still soft enough. Besides, I’m not certain that swage able alloys can even be precipitation hardened.

Wobbley- Admin

- Posts : 4653

Join date : 2015-02-12

Re: 148g HBWC skirt separation

Re: 148g HBWC skirt separation

I wouldn't worry about those.50 year olds maybe.

Ed Hall had some separate at Perry 10 years ago. I don't think they were hot loaded. He had 2 holes for each shot

Ed Hall had some separate at Perry 10 years ago. I don't think they were hot loaded. He had 2 holes for each shot

Re: 148g HBWC skirt separation

Re: 148g HBWC skirt separation

Re: 148g HBWC skirt separation

I wouldn't worry about those.50 year olds maybe.

Bruce,

Thanks for the feedback.

Doug

djw1cav- Posts : 200

Join date : 2015-04-06

Age : 75

Location : Illinois

Re: 148g HBWC skirt separation

Re: 148g HBWC skirt separation

Greetings,

A Lead fouled barrel can lead to "skirt separation".

The increased resistance of the next bullet traversing over the patch of Lead fouling in the barrel may cause the bullet to pull apart/separate due to the increased drag and pressure.

I had this happen several times firing a K32 revolver. The target had twelve holes after a ten shot string. The next target had little hollow base skirts stuck in the target. You could pick them out with your fingers.

I realize folks do not like to clean their guns; but, this is a good example of the effort well spent.

Cheers,

Dave

A Lead fouled barrel can lead to "skirt separation".

The increased resistance of the next bullet traversing over the patch of Lead fouling in the barrel may cause the bullet to pull apart/separate due to the increased drag and pressure.

I had this happen several times firing a K32 revolver. The target had twelve holes after a ten shot string. The next target had little hollow base skirts stuck in the target. You could pick them out with your fingers.

I realize folks do not like to clean their guns; but, this is a good example of the effort well spent.

Cheers,

Dave

fc60- Posts : 1390

Join date : 2011-06-11

Location : South Prairie, WA 98385

Re: 148g HBWC skirt separation

Re: 148g HBWC skirt separation

I had a severe leading problem with leading using Zero HBWCs in my .38spl 1911 and tried several different loads till I gave them a wash in a bowl/plastic tub with just enough liquid Rooster lube to cover them when swirled around in the bowl/plastic tub then set aside to dry over night. Bullets must be dry before loading and only air dried. I do this with Zero .45 185gr LSWCHPs also and find a good bit of lead slivers of lead in the bottom of the bowl after removing the bullets with a pair of large tweezers bought from Harbor Freight and set them on a piece of wax paper or alum foil to dry.

Rodger Barthlow- Posts : 345

Join date : 2013-08-10

Re: 148g HBWC skirt separation

Re: 148g HBWC skirt separation

Back in around 2011 Zero had a batch of 38 spl 148 hbwc that would lead unbelievable bad. I spoke with owner of Zero about it in 2013. He apologized and said they did have a bad run of bullets.

I'm talking 50+% of barrel leading. Horrible!

Jon

I'm talking 50+% of barrel leading. Horrible!

Jon

Jon Eulette- Posts : 4399

Join date : 2013-04-15

Location : Southern Kalifornia

Re: 148g HBWC skirt separation

Re: 148g HBWC skirt separation

skirt seperation is going to be a combination of

bore to bullet fit

powder charge

powder used, some have different pressure curves.. and some are going to give you more then expected in comparison to more popular options

lead alloy used and heat treating done

bullet cross section

bore to bullet fit

powder charge

powder used, some have different pressure curves.. and some are going to give you more then expected in comparison to more popular options

lead alloy used and heat treating done

bullet cross section

Eindecker- Posts : 144

Join date : 2022-10-08

Similar topics

Similar topics» All this 148G HBWC talk....

» Learning through mistake - Skirt blew off

» 148g Button nose 38 ?

» Zero 38 HBWC

» Best HBWC for S&W 52

» Learning through mistake - Skirt blew off

» 148g Button nose 38 ?

» Zero 38 HBWC

» Best HBWC for S&W 52

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum|

|

|