Ranson Rest vs. Linear Slide (Testing)

+10

pgg

bruce martindale

Wes Lorenz

fc60

jglenn21

S148

NukeMMC

james r chapman

Jon Eulette

tovaert

14 posters

Page 1 of 2

Page 1 of 2 • 1, 2

Ranson Rest vs. Linear Slide (Testing)

Ranson Rest vs. Linear Slide (Testing)

I read in the past that the design theory behind the RR is that it mimics the shooter's wrist and thus recoils via pivoting, impeded by a spring-loaded torsion-friction plate consisting of some unknown friction material(s) (sensitive to humidity, flatness, trapped wear debris, hysteresis, and temperature, to name a few). My RR is inconsistent in recoil (as measured by a goniometer), despite very precise loads whose MV varies in the single digits (ES), all else remaining the same. I most often get vertical stringing and sometimes wild side-to-side variation, from the same gun, which, tested not long before that, yielded very good groups (all else the same!). The manual offers very few suggestions for "fixes". I've also read about a wide variety of opinions on grip tensioning, or the degree of grip compression as measured by gap thickness between the polymer blocks, whose thickness can vary, which then affects the clamping force for a given gap.

I'm curious if anyone has ever removed the friction material and instead installed a ball or roller thrust bearing creating a frictionless pivot, and braked the device another way (spring/air-damper, etc.)? That removes the variation in friction properties of the pivot material. I thought I read something about a gunsmith with something that functioned like that, but I can't recall who that was.

On the other hand, I was watching a video a while back where Swiss P210s were tested at 50m. They were using a mount attached to a linear ball-bearing slide, impeded by a damping device, with no pivoting recoil. The pistol recoiled straight back. If you tested the same pistol using the two methods, and there was statistically-relevant variation in group size (all else the same), what could cause the variation? Differences in unlocking time? Bushing/barrel friction? Slide/frame friction? I'm referring to 1911s BTW...

I have a linear ball-bearing slide, and it would be easy to fashion something to hold RR grips, a brake, and use a remote trigger mechanism for testing.

I'm curious if anyone has ever removed the friction material and instead installed a ball or roller thrust bearing creating a frictionless pivot, and braked the device another way (spring/air-damper, etc.)? That removes the variation in friction properties of the pivot material. I thought I read something about a gunsmith with something that functioned like that, but I can't recall who that was.

On the other hand, I was watching a video a while back where Swiss P210s were tested at 50m. They were using a mount attached to a linear ball-bearing slide, impeded by a damping device, with no pivoting recoil. The pistol recoiled straight back. If you tested the same pistol using the two methods, and there was statistically-relevant variation in group size (all else the same), what could cause the variation? Differences in unlocking time? Bushing/barrel friction? Slide/frame friction? I'm referring to 1911s BTW...

I have a linear ball-bearing slide, and it would be easy to fashion something to hold RR grips, a brake, and use a remote trigger mechanism for testing.

tovaert- Posts : 432

Join date : 2018-11-28

Re: Ranson Rest vs. Linear Slide (Testing)

Re: Ranson Rest vs. Linear Slide (Testing)

HEG rest has a vertical arm and rigid mounting of pistol at the end of the arm. Then it has spring(s) that stretch to absorb the recoil and return arm/pistol to original position. So the radial movement of the arm combined with the spring(s) absorbs the recoil. Being radial in movement possibly assist with the pistol remaining consistent in its position in its attachment to the arm.

I’ve seen rail type rest for rifles that were extremely heavy used by the AMU. They are linear and rely on weight of the sliding carriage moving on an oiled bed. So I assume it only moves linearly because carriage is held in place by gravity on a V-bed.

So your system might work.

Pivoting system like RR needs the clutch disc to slow down the recoiling pistol/rest.

If free to move it would need a shock absorber or something to dampen the recoil force.

The weakness or flaw in RR is the inserts. There are people really good at using it, which are few. You have to use it a lot to master it.

My 2 cents

Jon

I’ve seen rail type rest for rifles that were extremely heavy used by the AMU. They are linear and rely on weight of the sliding carriage moving on an oiled bed. So I assume it only moves linearly because carriage is held in place by gravity on a V-bed.

So your system might work.

Pivoting system like RR needs the clutch disc to slow down the recoiling pistol/rest.

If free to move it would need a shock absorber or something to dampen the recoil force.

The weakness or flaw in RR is the inserts. There are people really good at using it, which are few. You have to use it a lot to master it.

My 2 cents

Jon

Jon Eulette- Posts : 4399

Join date : 2013-04-15

Location : Southern Kalifornia

Re: Ranson Rest vs. Linear Slide (Testing)

Re: Ranson Rest vs. Linear Slide (Testing)

Linear might also require clamping the slide ?

james r chapman- Admin

- Posts : 6233

Join date : 2012-01-31

Age : 75

Location : HELL, Michigan

Re: Ranson Rest vs. Linear Slide (Testing)

Re: Ranson Rest vs. Linear Slide (Testing)

Have you used the 3D printed grip inserts for the RR? Since they're plastic instead of rubber, I wonder if they are easier to "master" than the RR rubber ones?Jon Eulette wrote:The weakness or flaw in RR is the inserts. There are people really good at using it, which are few. You have to use it a lot to master it.

My 2 cents

Jon

I just got a set for HS 106/107. May have to get a set of 1911 to do a side-by-side with my RR inserts.

NukeMMC- Posts : 531

Join date : 2018-10-12

Re: Ranson Rest vs. Linear Slide (Testing)

Re: Ranson Rest vs. Linear Slide (Testing)

I tried one the plastic grip but it did not fit very well. That was for a Sig P210A. I would be curious about your findings for a 1911.NukeMMC wrote:Have you used the 3D printed grip inserts for the RR? Since they're plastic instead of rubber, I wonder if they are easier to "master" than the RR rubber ones?

I just got a set for HS 106/107. May have to get a set of 1911 to do a side-by-side with my RR inserts.

tovaert- Posts : 432

Join date : 2018-11-28

Re: Ranson Rest vs. Linear Slide (Testing)

Re: Ranson Rest vs. Linear Slide (Testing)

Thanks for the suggestions Jon. If I replace the clutch disc with a ball bearing, I've eliminated one variable. Rotation would be resisted by say putting foam just above the slide (a small gap). In theory, I could adjust that gap so that the bullet has exited the barrel, before the slide touches the foam. The advantage is that the downward force (and thus the upward reaction force) on the RR height adjustment screw, IMHO one source of vertical stringing, would be identical from shot-to-shot. The linear slide is simpler, but still requires some sort of grip. I wonder if the foam Ransom grips would survive the torque-moment of a linear tester. The plastic grips may be better. Perhaps a Winter project.Jon Eulette wrote:Pivoting system like RR needs the clutch disc to slow down the recoiling pistol/rest.

If free to move it would need a shock absorber or something to dampen the recoil force.

The weakness or flaw in RR is the inserts. There are people really good at using it, which are few. You have to use it a lot to master it.

My 2 cents

Jon

tovaert- Posts : 432

Join date : 2018-11-28

Re: Ranson Rest vs. Linear Slide (Testing)

Re: Ranson Rest vs. Linear Slide (Testing)

tovaert wrote:My RR is inconsistent in recoil (as measured by a goniometer), despite very precise loads whose MV varies in the single digits (ES), all else remaining the same. I most often get vertical stringing and sometimes wild side-to-side variation, from the same gun, which, tested not long before that, yielded very good groups (all else the same!). The manual offers very few suggestions for "fixes". I've also read about a wide variety of opinions on grip tensioning, or the degree of grip compression as measured by gap thickness between the polymer blocks, whose thickness can vary, which then affects the clamping force for a given gap.

How much variation do you see in the goniometer readings? Does the variation correlate with the bullet speed?

You might find this article of interest: http://www.shootingtimes.com/editorial/measure-relative-handgun-recoil/99442

S148- Posts : 298

Join date : 2017-07-04

Re: Ranson Rest vs. Linear Slide (Testing)

Re: Ranson Rest vs. Linear Slide (Testing)

How often do you see vertical stringing? If it is a problem with the RR, it should happen for every group.

How much vertical stringing? Are hits inches away from the main group?

How many rounds do you fire for your groups?

How much vertical stringing? Are hits inches away from the main group?

How many rounds do you fire for your groups?

S148- Posts : 298

Join date : 2017-07-04

Re: Ranson Rest vs. Linear Slide (Testing)

Re: Ranson Rest vs. Linear Slide (Testing)

A pull type shock absorber sometimes called a gas spring could be used to manage the recoil. The caldwell HMMR used this to manage the recoil movementof the pistols tested in it. The HMMR was an inexpensive copy of the RR

jglenn21- Posts : 2588

Join date : 2015-04-07

Age : 76

Location : monroe , ga

Re: Ranson Rest vs. Linear Slide (Testing)

Re: Ranson Rest vs. Linear Slide (Testing)

Thanks for the article reference. In my case, there was no apparent connection w/MV. I'm testing in the 650 (.45) to 900 (9mm) fps range. I've seen about 3 degrees total angular variation, with single digit MV ES. I don't think that should happen, but I could be wrong. It's been a constant problem. I test when temperatures are in the 70 to 80F range. Typically groups are ~2" wide and 4" high (or greater). I fire 10 shot groups at 50 yards. My RR has not been disassembled nor have I tightened/loosened the compression spring. IMHO the range's base setup is good: 1/2" steel plate welded to 4" diameter steel legs that are buried in concrete. It was built for the RR, but it's not a solid block of concrete as some use.S148 wrote:How often do you see vertical stringing? If it is a problem with the RR, it should happen for every group.

How much vertical stringing? Are hits inches away from the main group?

How many rounds do you fire for your groups?

I got frustrated when I was testing a Sig P210A (with RR frame grips), then shooting tighter groups off of a cheap pistol rest with a red dot installed. Last winter I finished modifying a new SA RO (9mm) with the usuals (new barrel, bushing, internals, etc.). The first photo is a RR-tested (9-shot) group. This is typical. More recently, Froneck designed/installed a new rail for me, so I started testing it again, same loads as before. The second photo is a 10 shot group using the same pistol rest (50 yards on B-6 target). When I test, my goal is to keep the red dot inside the orange paster, and steadily increase trigger pressure. I know that this method is sensitive to any downward or lateral pressure between the dust cover and the rubber channel in the pistol rest, and grip consistency. I use a two-handed grip.

My suspicion is that my RR varies in how it reacts and rotates after ignition. Friction is inconsistent and perhaps it shows up with slower rounds? I also struggle with understanding the ins and outs of RR grip "adjustment." Some use a torque wrench, some use a defined gap between the two grips, others follow the instructions.

Last edited by tovaert on 10/22/2022, 10:25 pm; edited 3 times in total

tovaert- Posts : 432

Join date : 2018-11-28

Re: Ranson Rest vs. Linear Slide (Testing)

Re: Ranson Rest vs. Linear Slide (Testing)

Second photo...

I should add that on each shot, I load one round in the mag, insert, and rack the slide with the barrel horizontal. I repeat this with every shot (using the same magazine). The load is a 147 XTP, 3.00 gr Alliant e^3, once-fired Starline brass, Fed 100 primer, 1.110" OAL, 0.376" to 0.377" "crimp".

I should add that on each shot, I load one round in the mag, insert, and rack the slide with the barrel horizontal. I repeat this with every shot (using the same magazine). The load is a 147 XTP, 3.00 gr Alliant e^3, once-fired Starline brass, Fed 100 primer, 1.110" OAL, 0.376" to 0.377" "crimp".

tovaert- Posts : 432

Join date : 2018-11-28

Re: Ranson Rest vs. Linear Slide (Testing)

Re: Ranson Rest vs. Linear Slide (Testing)

Greetings,

When needed, I use the Random Rest for testing.

I have found that cleaning the friction disks per Ransom's instructions does help.

The fiber disk will get a glaze from use and causes erratic movement.

When returning the rest to the stop, it should be a smooth movement. If you feel any "jitter/jerking" it is not repeating correctly.

Also, do you get vertical stringing when testing a revolver?

I have found that with the autoloader vertical stringing may be caused by too weak a recoil spring. The barrel is not being restrained consistently during recoil.

Try it. Swap out a heavier spring and observe the group shape. Use as heavy a spring as you can with the slide still locking back on the last shot.

The Random Rest holds harder than most of us off hand.

Cheers,

Dave

When needed, I use the Random Rest for testing.

I have found that cleaning the friction disks per Ransom's instructions does help.

The fiber disk will get a glaze from use and causes erratic movement.

When returning the rest to the stop, it should be a smooth movement. If you feel any "jitter/jerking" it is not repeating correctly.

Also, do you get vertical stringing when testing a revolver?

I have found that with the autoloader vertical stringing may be caused by too weak a recoil spring. The barrel is not being restrained consistently during recoil.

Try it. Swap out a heavier spring and observe the group shape. Use as heavy a spring as you can with the slide still locking back on the last shot.

The Random Rest holds harder than most of us off hand.

Cheers,

Dave

fc60- Posts : 1390

Join date : 2011-06-11

Location : South Prairie, WA 98385

Re: Ranson Rest vs. Linear Slide (Testing)

Re: Ranson Rest vs. Linear Slide (Testing)

Thanks for the suggestions Dave. My RR has really had relatively little use. I have not cleaned the discs...and I don't own a revolver.fc60 wrote:Also, do you get vertical stringing when testing a revolver?

I have found that with the autoloader vertical stringing may be caused by too weak a recoil spring. The barrel is not being restrained consistently during recoil.

Try it. Swap out a heavier spring and observe the group shape. Use as heavy a spring as you can with the slide still locking back on the last shot.

The Random Rest holds harder than most of us off hand.

Cheers,

Dave

Yes...light recoil springs in the SA RO (8 or 9#). As I mentioned above, I'm shooting soft loads. I was under the impression that group size will be affected by the recoil spring, so I try to test with the one I would typically use. I have heavier ones...but are the results relevant?

tovaert- Posts : 432

Join date : 2018-11-28

Re: Ranson Rest vs. Linear Slide (Testing)

Re: Ranson Rest vs. Linear Slide (Testing)

Greetings Tovaert,

With the 1911 design the bullet should exit the barrel before the barrel link starts to pull the barrel down. This is about 0.05" of rearward movement.

Shooting off hand, you select the recoil spring that just locks the slide back on the last round. Properly fit, the bullet should have exited the barrel before the link starts to pull the barrel down.

With the Random Rest, it "holds harder" than an offhand shooter. So, with a weak recoil spring the barrel might start to move downward before the bullet exits.

I had this issue with a 1911 Hard Ball gun years back. I initially got a 2" wide by 6" tall group with Match Ball ammo. I removed the recoil spring and replaced it with a much heavier one, the slide would still lock back on the last round. and the resultant group was a nice round 2".

We need someone fluent in Dynamics to study the Random Rest and write a paper explaining all the forces displayed withing the tool.

Cheers,

Dave

With the 1911 design the bullet should exit the barrel before the barrel link starts to pull the barrel down. This is about 0.05" of rearward movement.

Shooting off hand, you select the recoil spring that just locks the slide back on the last round. Properly fit, the bullet should have exited the barrel before the link starts to pull the barrel down.

With the Random Rest, it "holds harder" than an offhand shooter. So, with a weak recoil spring the barrel might start to move downward before the bullet exits.

I had this issue with a 1911 Hard Ball gun years back. I initially got a 2" wide by 6" tall group with Match Ball ammo. I removed the recoil spring and replaced it with a much heavier one, the slide would still lock back on the last round. and the resultant group was a nice round 2".

We need someone fluent in Dynamics to study the Random Rest and write a paper explaining all the forces displayed withing the tool.

Cheers,

Dave

fc60- Posts : 1390

Join date : 2011-06-11

Location : South Prairie, WA 98385

Re: Ranson Rest vs. Linear Slide (Testing)

Re: Ranson Rest vs. Linear Slide (Testing)

I’d suggest watching one of the many random rest videos put up by AXI (steve huff).

james r chapman- Admin

- Posts : 6233

Join date : 2012-01-31

Age : 75

Location : HELL, Michigan

Re: Ranson Rest vs. Linear Slide (Testing)

Re: Ranson Rest vs. Linear Slide (Testing)

I went to the website and YouTube watched them. I use his same set/reset method, and he has a concrete base. Other than that, there is nothing educational regarding RR testing (grip fit, compression, RR modification, etc.). Everything is geared towards test groups of his guns.james r chapman wrote:I’d suggest watching one of the many random rest videos put up by AXI (steve huff).

tovaert- Posts : 432

Join date : 2018-11-28

Re: Ranson Rest vs. Linear Slide (Testing)

Re: Ranson Rest vs. Linear Slide (Testing)

Thanks Dave...that's interesting that you were able to get those results. The bottom line question though remains...is the gun accuracy affected by recoil spring weight? Since you would then (I assume) change the recoil spring back to the lighter one for offhand shooting, would that gun (as sprung) still group @ 2"?fc60 wrote:I had this issue with a 1911 Hard Ball gun years back. I initially got a 2" wide by 6" tall group with Match Ball ammo. I removed the recoil spring and replaced it with a much heavier one, the slide would still lock back on the last round. and the resultant group was a nice round 2".

tovaert- Posts : 432

Join date : 2018-11-28

Re: Ranson Rest vs. Linear Slide (Testing)

Re: Ranson Rest vs. Linear Slide (Testing)

I just don't limp wrist and then have to perform all of this recoil spring changing. Shoot loads matched to a recoil spring that just stays open offhand.

KISS method - then test that setup in the RR.

KISS method - then test that setup in the RR.

Wes Lorenz- Posts : 426

Join date : 2011-06-27

Location : Washington

Jon Eulette likes this post

Re: Ranson Rest vs. Linear Slide (Testing)

Re: Ranson Rest vs. Linear Slide (Testing)

I work on lots of guns. I’ve worked on guns built by nearly every old school gunsmith and many of the current gunsmiths. Most barrels unlock prematurely due to practically no bottom lug contact with the slide stop. Those pistols seem to always shoot better with heavier recoil springs and medium to heavy loads. I firmly believe that barrels that are fit like this are unforgiving to shoot from hand. There is more recoil from slide traveling faster because barrel unlocks sooner. But from a RR these pistols can group very well. RR can provide repeatability that a shooter cannot replicate. It’s nice having a good RR group, but if you can’t shoot good groups from hand what good is the RR group? A few years back a 2670 shooter gave me his new $$$$ pistol to look at. He said he couldn’t shoot it well and wanted me to look it over. RR target that came with pistol was 1.5”. I ended up rebarreling the pistol and that pistol has shot 890’s, 2660’s and broke national records. The original pistol upper barrel lugs were not fit and minimum bottom lug engagement with slide stop pin. Was unlocking too fast. Makes for very unforgiving pistol. Most gunsmiths do not hard fit barrels anymore. Why? It takes longer to build and time is money. Bottom lugs used to be hand fit. Now majority of gunsmiths mill cut bottom lugs. In most cases they are removing too much and lockup ends up with vertical play. This play will affect slide velocity and barrel unlocking; faster and too quick. So throw an Aimpoint 9000 on it and call it good. Heavy scope slows things down. I’ve RR old worn guns and new builds. The old builds always rotate further than a new build with the same load. I’ve taken physic’s, static’s and dynamic’s in college. I had a professor try and help me figure out recoil forces in a 1911. We never completed the problem. We have many factors taking place. Obviously the force of the cartridge case (blow back), but add frictional forces from hood sliding down breechface, bottom lugs on slide stop pin, upper lugs coming out of slide lugs, bushing to barrel friction, slide to frame friction, hammer to firing pin stop friction, disconnector friction, hammer cocking rotational force, mainspring and recoil spring forces, magazine friction (follower/cartridge) energy lost to RR insert (flexing), RR weight/mass (rotational) and RR friction clutches. Probably more…..

Consistency and repeatability are keys to getting good RR results. Ultimately a good pistol, good ammunition and experience using RR are all important to getting good results.

I’d like to see a linear fixture….just because:)

Jon

Consistency and repeatability are keys to getting good RR results. Ultimately a good pistol, good ammunition and experience using RR are all important to getting good results.

I’d like to see a linear fixture….just because:)

Jon

Jon Eulette- Posts : 4399

Join date : 2013-04-15

Location : Southern Kalifornia

bruce martindale, NuJudge, chopper, jglenn21, DA/SA, tovaert, Thin Man and 22Cool like this post

Re: Ranson Rest vs. Linear Slide (Testing)

Re: Ranson Rest vs. Linear Slide (Testing)

Greetings,

Thanks (Two snaps and a twist) to Jon for the added explanation. To me, it appears that the heavier spring keeps the lower barrel lugs in contact longer allowing the bullet to exit uniformly.

Why test ammo in the Random Rest?

I have tested ammo for fellow shooters that would not hold the repair center at 50 yards. Assuming the shooter has an X-ring hold, 8-ring ammo does not score well. If you have an 8-ring hold, the combination becomes much worse.

To be redundant, this is why 22lr ammo is such a good training aid. Most quality SV ammo will hold the X-ring.

Cheers,

Dave

Thanks (Two snaps and a twist) to Jon for the added explanation. To me, it appears that the heavier spring keeps the lower barrel lugs in contact longer allowing the bullet to exit uniformly.

Why test ammo in the Random Rest?

I have tested ammo for fellow shooters that would not hold the repair center at 50 yards. Assuming the shooter has an X-ring hold, 8-ring ammo does not score well. If you have an 8-ring hold, the combination becomes much worse.

To be redundant, this is why 22lr ammo is such a good training aid. Most quality SV ammo will hold the X-ring.

Cheers,

Dave

fc60- Posts : 1390

Join date : 2011-06-11

Location : South Prairie, WA 98385

bruce martindale likes this post

Re: Ranson Rest vs. Linear Slide (Testing)

Re: Ranson Rest vs. Linear Slide (Testing)

I think Jon's explanation is one of the best l have read. I would sticky that!

Re: Ranson Rest vs. Linear Slide (Testing)

Re: Ranson Rest vs. Linear Slide (Testing)

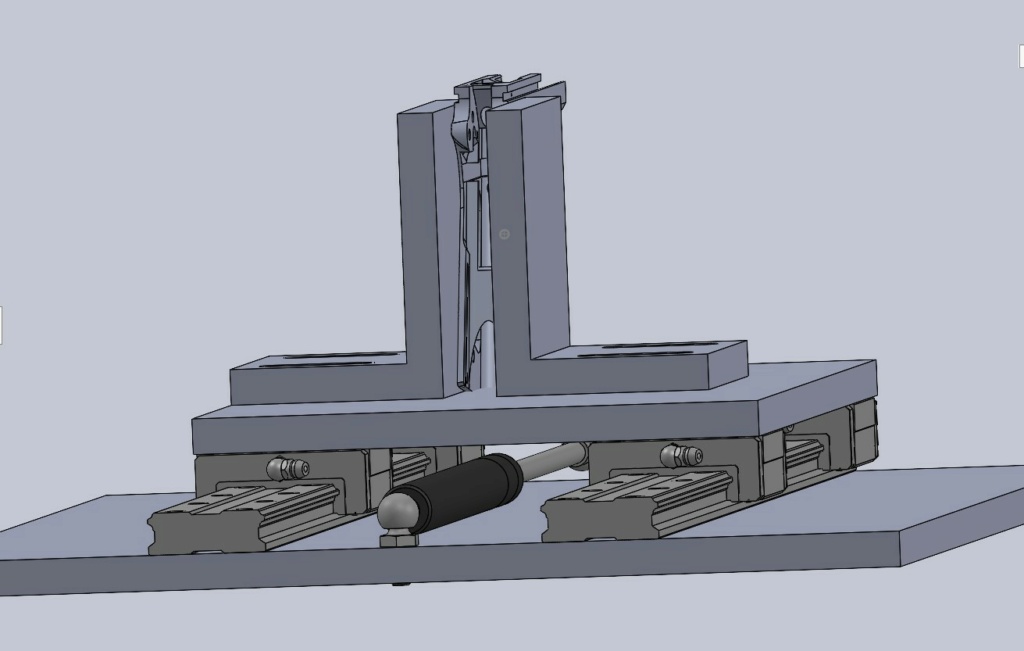

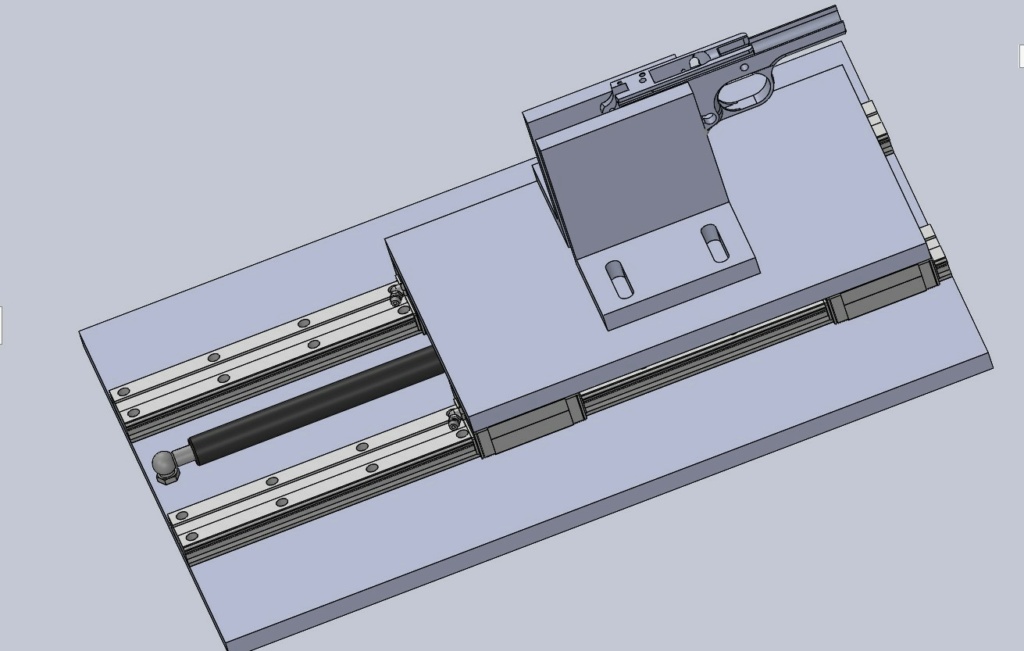

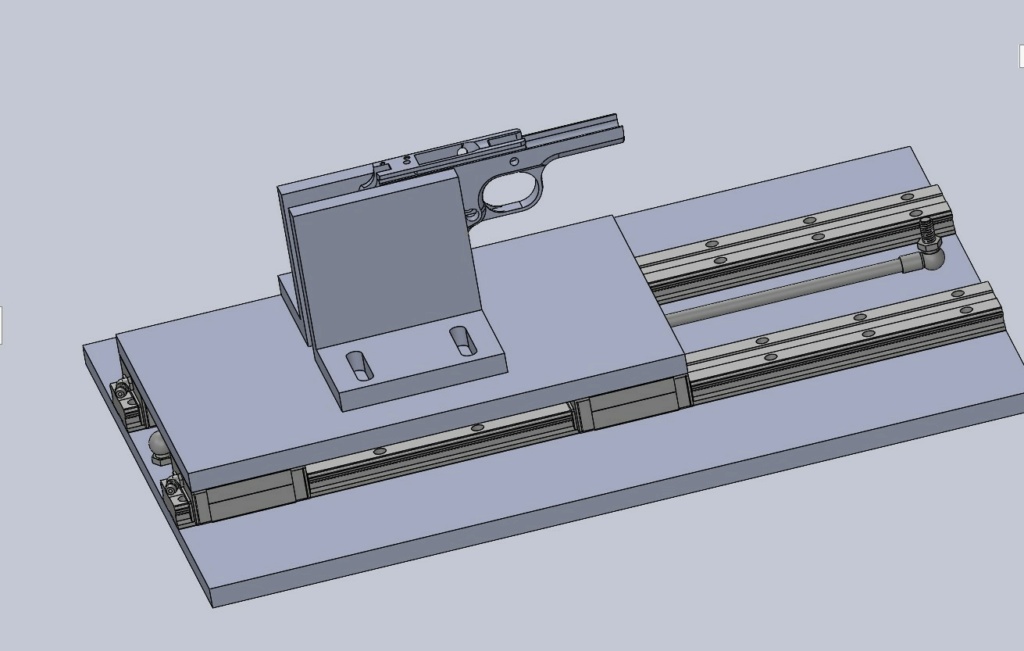

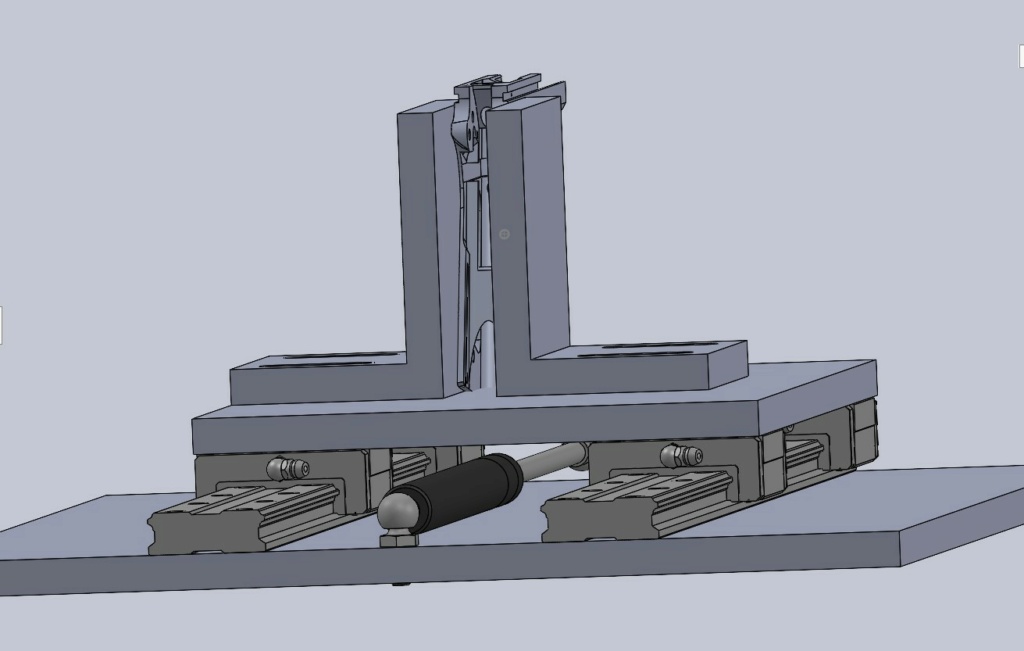

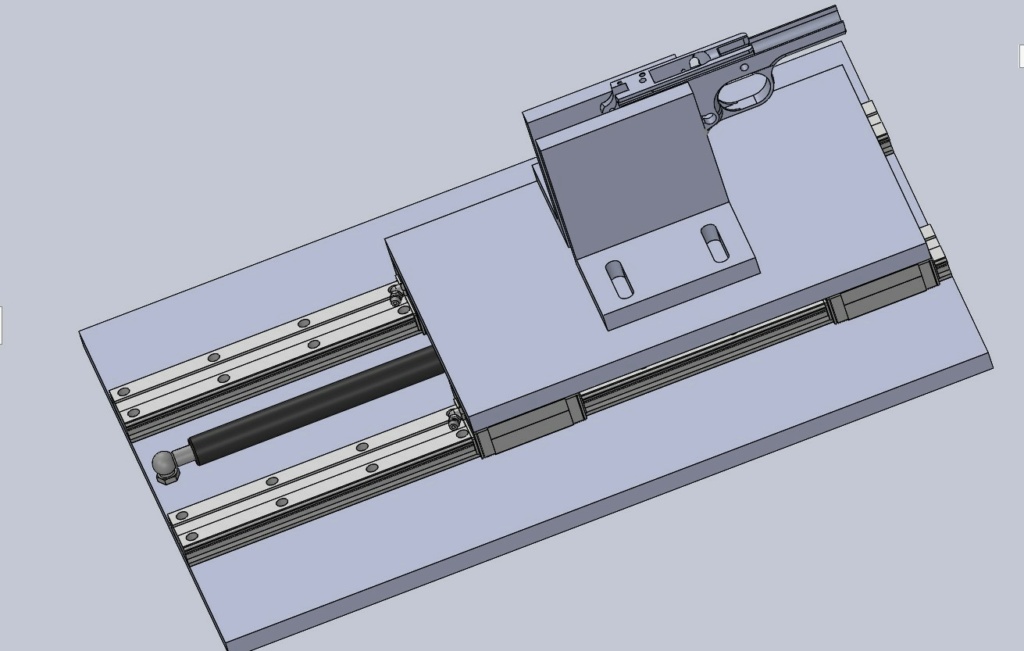

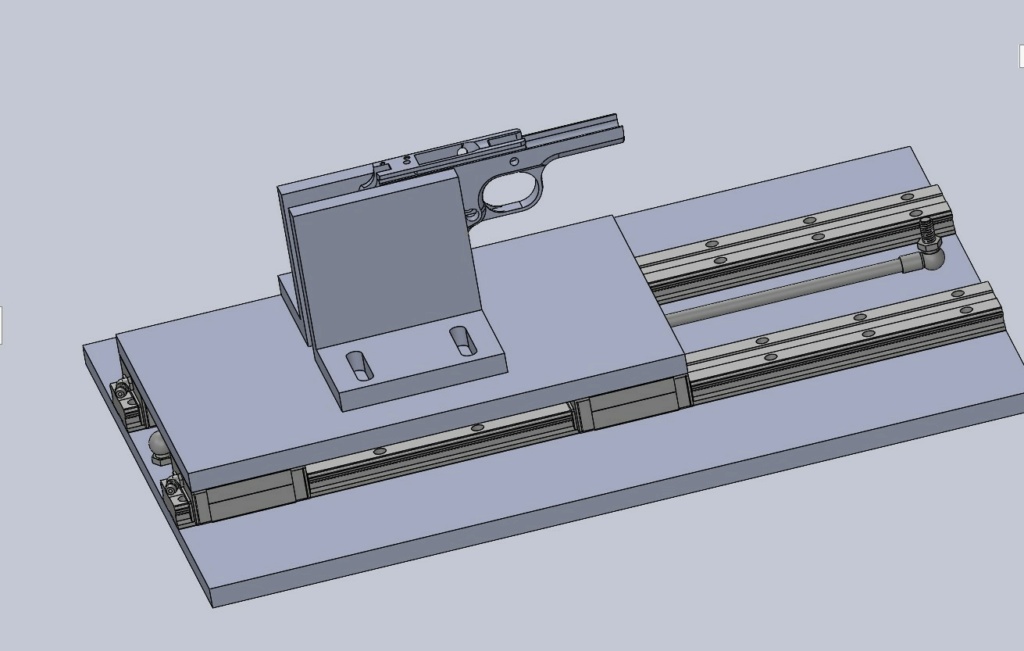

how about this for a linear concept. please, no commentary on the crude drawing and lack of detail, just threw it together this am while waiting for the dr. the gun would probably be held by ransom rest inserts... or not... triggering would be via a small mechanism attached to the front of the trigger guard, like a small air cylinder or similar, I've never liked the trigger mechanism on the RR.

linear rails can be had for reasonable money and a shimmed slot on the base can be used to take out deviation by moving the rails appart and forcing the carrages onto one side of the bearing cage. gas spring to retard recoil and return the assembly forward for next shot.

https://www.amazon.com/CHUANGNENG-Linear-HGH20CA-Carriage-Routers/dp/B08HGZFH8L/ref=sr_1_8?crid=14UL04CW2XGMX&keywords=linear%2Bguide%2Brail&qid=1666705872&qu=eyJxc2MiOiI2Ljg4IiwicXNhIjoiNi4xMSIsInFzcCI6IjUuMTYifQ%3D%3D&sprefix=linear%2Bguide%2Brail%2Caps%2C130&sr=8-8&ufe=app_do%3Aamzn1.fos.f5122f16-c3e8-4386-bf32-63e904010ad0&th=1

these are not the rails used in the drawing, but would work as our forces and reps are relativly low

linear rails can be had for reasonable money and a shimmed slot on the base can be used to take out deviation by moving the rails appart and forcing the carrages onto one side of the bearing cage. gas spring to retard recoil and return the assembly forward for next shot.

https://www.amazon.com/CHUANGNENG-Linear-HGH20CA-Carriage-Routers/dp/B08HGZFH8L/ref=sr_1_8?crid=14UL04CW2XGMX&keywords=linear%2Bguide%2Brail&qid=1666705872&qu=eyJxc2MiOiI2Ljg4IiwicXNhIjoiNi4xMSIsInFzcCI6IjUuMTYifQ%3D%3D&sprefix=linear%2Bguide%2Brail%2Caps%2C130&sr=8-8&ufe=app_do%3Aamzn1.fos.f5122f16-c3e8-4386-bf32-63e904010ad0&th=1

these are not the rails used in the drawing, but would work as our forces and reps are relativly low

10sandxs- Posts : 946

Join date : 2016-01-29

chopper likes this post

Re: Ranson Rest vs. Linear Slide (Testing)

Re: Ranson Rest vs. Linear Slide (Testing)

Ditch the RR inserts and simply hold the pistol by The grip screw inserts.. i have an weigand frame holder that uses that concept. Works well

jglenn21- Posts : 2588

Join date : 2015-04-07

Age : 76

Location : monroe , ga

Re: Ranson Rest vs. Linear Slide (Testing)

Re: Ranson Rest vs. Linear Slide (Testing)

Have to build in some elevation and deflection methods but could be kept very simple

jglenn21- Posts : 2588

Join date : 2015-04-07

Age : 76

Location : monroe , ga

Re: Ranson Rest vs. Linear Slide (Testing)

Re: Ranson Rest vs. Linear Slide (Testing)

tovaert wrote:Second photo...

I should add that on each shot, I load one round in the mag, insert, and rack the slide with the barrel horizontal. I repeat this with every shot (using the same magazine). The load is a 147 XTP, 3.00 gr Alliant e^3, once-fired Starline brass, Fed 100 primer, 1.110" OAL, 0.376" to 0.377" "crimp".

I've found with my RR that letting the pistol load itself in recoil for each measured shot gets the most consistent results. So I

- load the magazine to capacity

- chamber a round

- top off the magazine

- send the first round high off paper into the berm (i.e. the manually cycled round)

- shoot the remaining rounds into the group on paper

For me the purpose of the RR is to remove as many human factors as possible from testing ammo.

pgg- Posts : 198

Join date : 2015-11-21

jglenn21 likes this post

Page 1 of 2 • 1, 2

Similar topics

Similar topics» Dealings With Bench Rest Testing a Revolver

» Nelson Conversion

» RANSOM REST TESTING

» Looking for Ransom rest testing

» Ransom Rest Testing

» Nelson Conversion

» RANSOM REST TESTING

» Looking for Ransom rest testing

» Ransom Rest Testing

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum|

|

|